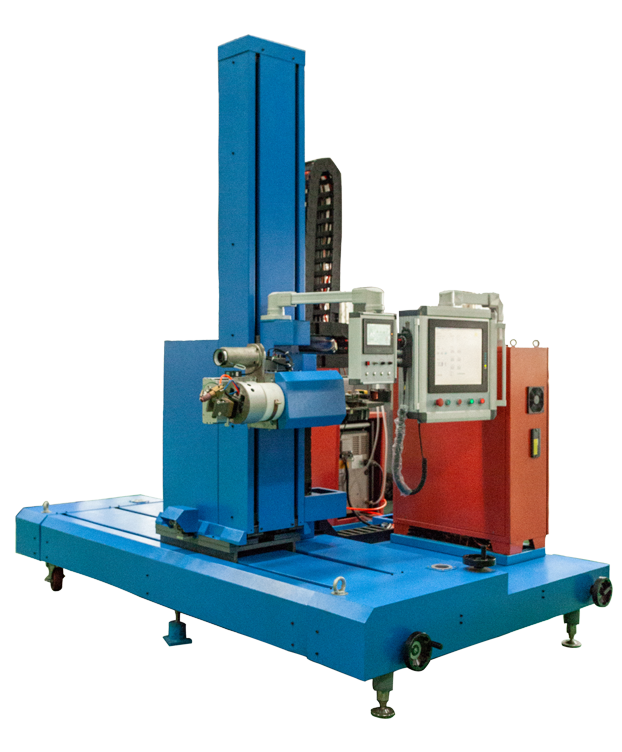

龙门全自动管板焊机

日期:2018-09-29 作者: 分类:分类二 浏览:次

龙门全自动管板焊机

WZM1-315C数控全位置脉冲氩弧焊机是专为电站锅炉、石油、化工、原子能、造船和轻工机械等工业中热交换器的生产而研制的专用设备.主要用于管子-管板焊缝的焊接.本设备适用于碳钢、不锈钢、钛合金、铜合金等金属进行全位置焊接,吸收了国内外管板焊机的先进技术,配以我公司自主设计编写的软件,焊接参数通过触摸屏设置,自动化程度高、故障率低。很好的弥补了过去这一领域进口焊机价格过高以及国产焊机和手工焊接操做不简捷、工作强度高等缺点。本产品经推出以来,受到抚顺化工机械厂、大连东方亿鹏设备制造有限责任公司、四川江源化工机械厂等广大用户的一致好评。

操作架焊接范围

| 横向移动行程 |

1500mm |

| 垂直移动行程 |

2000mm |

| 最低焊接高度 |

550mm |

产品性能

- 采用西门子公司生产的可编程序控制器(PLC)控制,安装我公司开发的软件,整个焊接过程根据预先设定的程序和工艺自动进行;

- 控制系统设计以人为本,操作简捷,全中文界面,工艺参数通过触摸屏输入,无需专业基础及特别语言;

- 龙门架三维调节配合三维微调,适合于管径和管桥较小的密集型换热器的焊接;

- 焊接机头能在水平面上180度旋转,便于更换钨极及送丝微调等操作;

- 机头的水、电、气采用了不缠绕方式,焊矩可以连续旋转配合弧长调节,可实现多层焊接;

- 机头采用水冷定位芯轴,避免管头熔化后内流,焊缝成型美观;

- 采用松下IGBT逆变控制直流脉冲电源。焊接效率高,电弧稳定性强,焊接成型美观;

- 电弧电流为脉冲波形,各参数均可单独设定,溶池容易控制,溶宽和溶深均匀一致;

- 具有81套程序存储功能,每套程序工艺参数都可修改。有空转运行、焊接运行两种工作方式;

- 焊接方式有四种:1、焊一层,不填丝;2、焊一层,填丝;3、焊二层,第一层不填丝,第二层填丝;4、焊二层均填丝。

主要技术参数

| 主要技术参数 |

单位 |

WZM-315C |

| 输入电源三相四线 |

V |

380±10% |

| 额定输出容量 |

KVA |

11 |

| 额定输入电流 |

A |

18 |

| 额定空载电压 |

V |

78 |

| 额定工作电流 |

A |

315 |

| 电流调节范围 |

A |

4-315 |

| 额定负载持续率 |

|

60% |

| 脉冲宽度调节范围 |

|

10-90% |

| 脉冲频率调节范围 |

1/S |

0.2-10 |

| 脉冲电流波形 |

|

方波 |

| 电流衰减时间调节范围 |

S |

>30 |

| 焊矩转速 |

r/min |

0.2-5 |

| 焊丝馈送速度 |

mm/min |

100-1500 |

| 可焊管子外径范围 |

mm |

Φ10-Φ80 |

| 氩气流量 |

L/min |

<15 |

Welding range for operation frame WZM1-315C

numerical controled automatically

tube-sheet welder is the special device for the manufacturing of the heat exchangeers in the industries of boiler, petroleum,chemical industry, atomic energy, shipbuilding, ect..It is mostly used in the welding of tubes and sheet.It is fit for the welding of carbon steel, stainless steel, titanic alloy, cupreous alloy etc..

Welding range for operation frame

| Transversely movement stroke |

1500mm |

| Vertical movement stroke |

2000mm |

| Lowest welding height |

550mm |

Functions and features of the product

- The welding machine adopts computer control ,the whole welding process shall be qutomatically conducted according to the preset procedures and process;

- The design of the control system takes the people as the fundamentality, it is convenient for operation, wiht friendly man-machine interface, technological parameters can be directly entered through the key board, without basic professional knowledge and special language;

- Portal frame 3-D adjustment coordinates with 3-D fine adjustment, adaptable to the welding of dense type heat exchanger with smaller pipe diameter and pipe bridge;

- Welding head can rotate in 180 degree on the horizontal plane, convenient for replacing tungsten electrode and the operation for wire feeding ect.;

- Water, electricity and air of welding head adopt mode without winding, weleing torch can continuously coordinate to the arc length for adjustment, can realize multi-layer welding;

- Welding head adopt water cooling positiong spindle ,which can avoid internal flowing after the pipe head being melted, the weld seam fprmation is good looking;

- Adopt Panasonic IGBT invert control DC pulse power supply. The welding efficiency is high, are stability is strong and the welding formation is good looking;

- Arc currentision pulse waveform, every parameter can be independently set, the bath can be easily controlled, the melting width is consistent to the melting depth;

- Possess with the selection of 7 gear fixed technological specification and one gear variable technological specification. With two working modes of idle running and normal running;

- 4 kind of welding modes: 1. Weld one layer, without filling the wire; 2.Weld one layer, fill the wire; 3.Weld two layers, no wire filling for the first layer, fill the second layer; 4. Weld two layers with wire filling.

Main technical parameters

| Main technical parameters |

Umit |

WZM-315C |

| Input power apply 3-phase 4 wires |

V |

380±10% |

| Rated output capacity |

KVA |

11 |

| Rated input current |

A |

18 |

| Rated no-load voltage |

V |

78 |

| Rated work current |

A |

315 |

| Current adjustment scope |

A |

4-315 |

| Rated load continuance rate |

|

60% |

| Pulse width adjustment scope |

|

10-90% |

| Pulse frequency regulation scope |

1/S |

0.2-10 |

| Pulse current waveform |

|

Square waver |

| Current attenuation regulation scope |

S |

>30 |

| Welding torch rate of rotation |

r/min |

0.2-5 |

| Welding wire feeding speed |

mm/min |

100-1500 |

| Outer diameter scope of pipe to be welded |

mm |

Φ10-Φ80 |

| Argon flowrate |

L/min |

<15 |